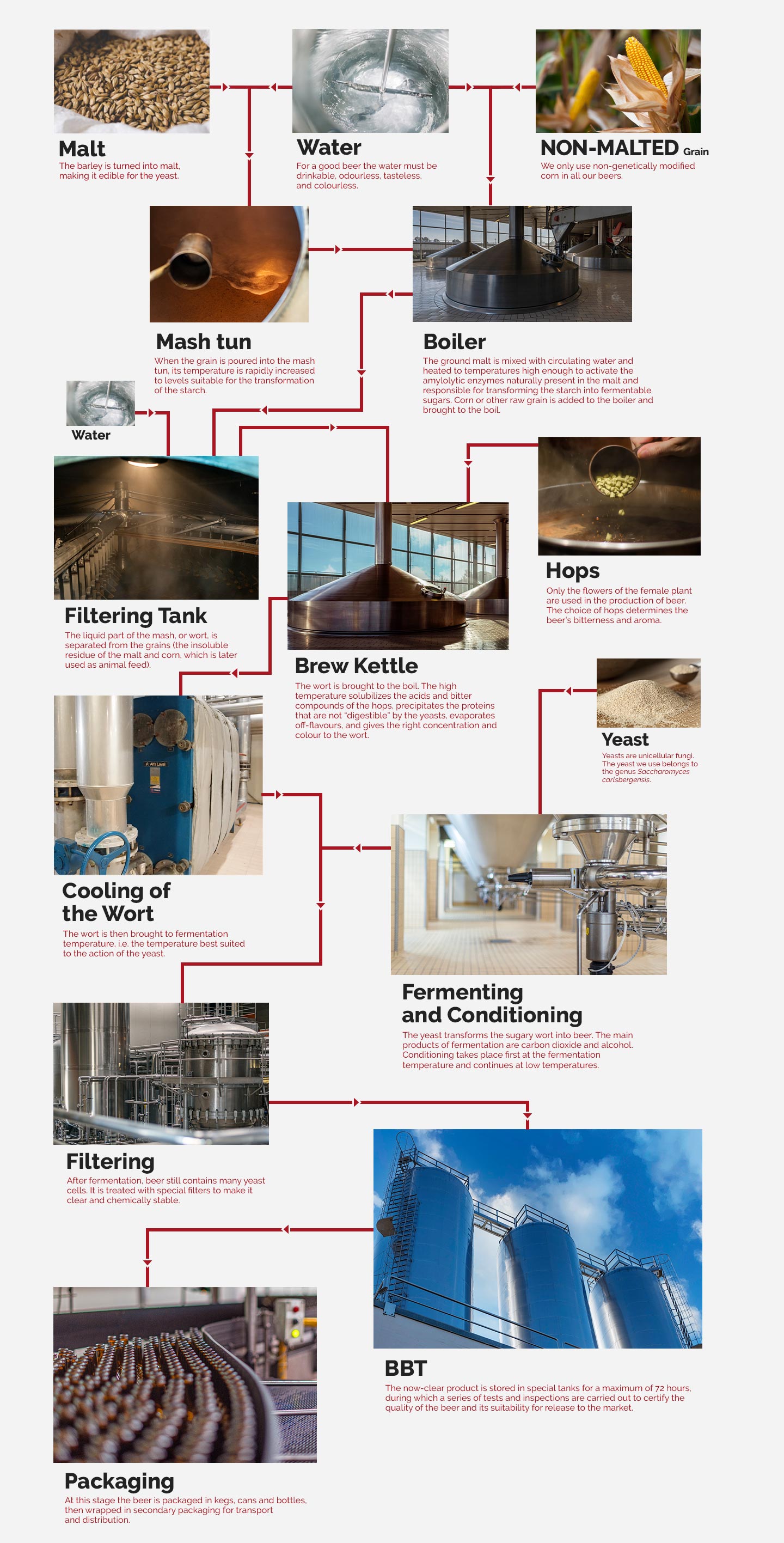

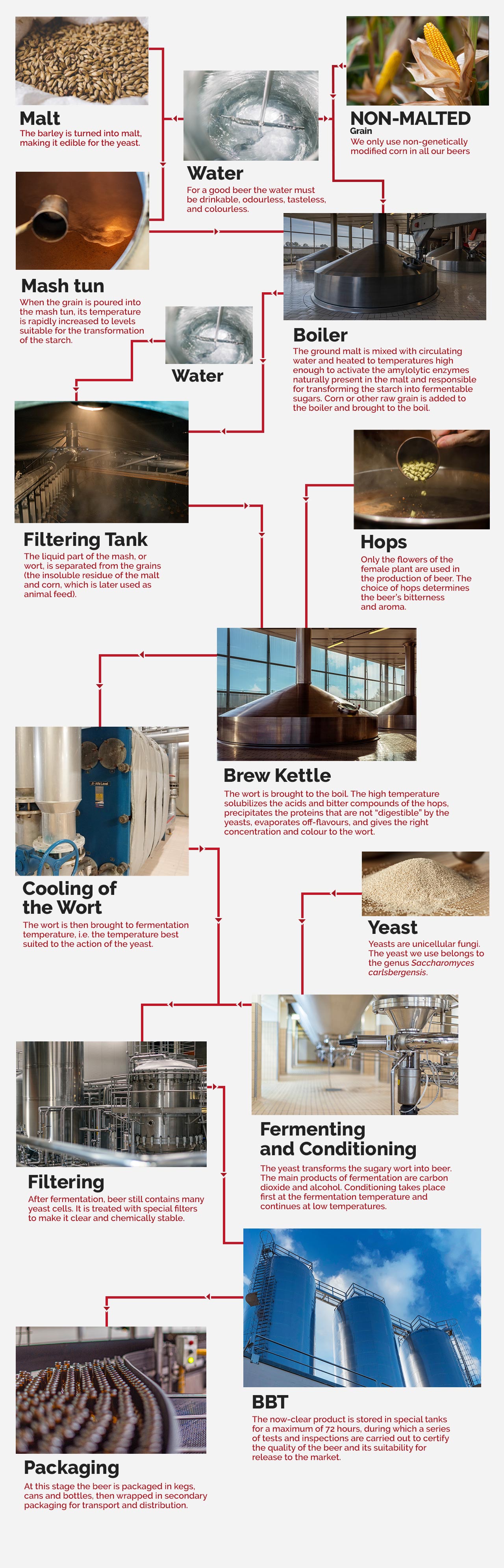

Innovation, passion, commitment, quality

We carefully oversee every phase in the production of our beers: from steeping the barley and other cereals to produce malt, through germination and drying to kilning and packaging.

Step 1

Steeping

The first phase of the production process involves the preparation of the barley, which is cleaned and graded so that only the largest and most homogeneous grains are approved for malting.

The selected barley is then poured into cylindrical tanks with conical bottoms, where it remains for about a day, alternately immersed in water or rested and aerated. During this time, the barley absorbs the water and oxygen necessary for the germination process to start, and reaches the required level of humidity (about 40%).

Step 2

Germination

Once it has reached the necessary level of humidity, the barley is transferred to germination boxes where the embryonic development process is monitored for 6 days. In this phase, aeration of the barley grains is very important, as it is necessary to remove the heat generated by cellular respiration. To keep the seeds in germination at a controlled temperature (between 12°C and 15°C), air is forced through the bottom of the germination boxes, consisting of perforated grilles.

Once the plumule – the sprout that is growing from the embryo – is the same length as the grain, the “green” malt or germinated barley is ready for drying.

Step 3

Drying

When the green malt arrives at this stage, its germination is stopped to make the product stable for storage and transport to the brewery. It’s also during the drying process that all those transformations take place that give the finished malt the aromatic characteristics typical of the beer in which it will be used. The drying process follows a special recipe with the temperature increased in increments to prevent damage to the enzymes and single molecules produced during germination. Only when the moisture content drops below 10% can the temperature be raised to over 80°C to give the malt its typical colour and aroma. At the end of the drying process the rootlets which developed during the barley’s germination phase are separated from the malt grain, as they contain substances harmful to the stability of the beer. With their high protein content, they’re valuable as animal feed.

Step 4

Mashing and decoction

The malt is then ground and mixed with process water and the resulting mash pumped into 2 boilers, where it’s processed in ideal conditions of time, temperature, and stirring to activate the amylolytic enzymes present in the malt, transforming its starches into fermentable sugars.

Step 5

Lautering

Lautering is a process consisting in the separation of the liquid wort from the solid malt husks, followed by the extraction of sugars using hot process water. All this takes place in a tank with a perforated bottom, using a rake to optimize the filtration process. A clear wort means an even-flavoured final product. The waste malt grains are used as feed for cattle.

Step 7

Adding

Hops

Another important operation during cooking and boiling is the addition of hops, which gives the beer its characteristic bitter taste and distinctive aroma. Hops act in different ways depending on their variety, the hopping method, and the moment the hops are added: they impart bitterness when added at the beginning of boiling, and flavour when added at the end. Hops help to clarify the beer and improve the stability of the foam.

The production sequence